Focus on Surface Finishing For 30 Years

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

Features

1. The long trough vibrating finishing line continuously feeds workpieces into the working trough through intervals, then the surface is polished by the long trough vibrating finishing machine, and finally the material is continuously fed in and out, which solves the problem that the current circular vibrating finishing cannot solve. 'Bump' problems in the process of workpiece finishing.

2. Through the PLC program control, the workpiece is transferred to the working groove of the long groove vibration finishing machine through the workpiece conveyor for polishing and deburring.Relying on the principle of spiral vibration, the long-trough vibrating finishing machine makes the workpiece pass through the deburring and polishing continuously, and the abrasive and the workpiece are discharged together to vibrating sorting and washing for screening. After screening, the workpiece is cleaned (it can also be used for rust prevention). The workpiece enters the next process, the abrasive returns to the abrasive conveyor, and the abrasive conveyor transports the abrasive to the abrasive screening mechanism to filter out the fine abrasive particles in the abrasive, effectively preventing the phenomenon of fine abrasive stuck to the workpiece, and the qualified abrasive enters the long-term The workpiece is processed continuously in the slot machine working slot.

3. Workpiece feeding to discharging time: adjustable from 10 minutes to 36 minutes.

configuration options

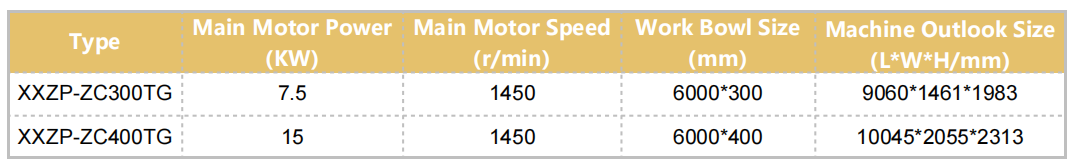

1. According to the requirements of the workpiece size, this type of equipment has different working slot widths for option: 300mm and 400mm.

2. Conveyor configuration: Workpieces and abrasives are added to the working trough of the vibrating finishing machine.

3. Vibration flushing mechanism: flush the workpiece.

4. Stainless steel mesh belt drying device: It can continuously dry workpieces online to ensure that the output efficiency of vibrating machine workpieces is consistent with the drying efficiency.

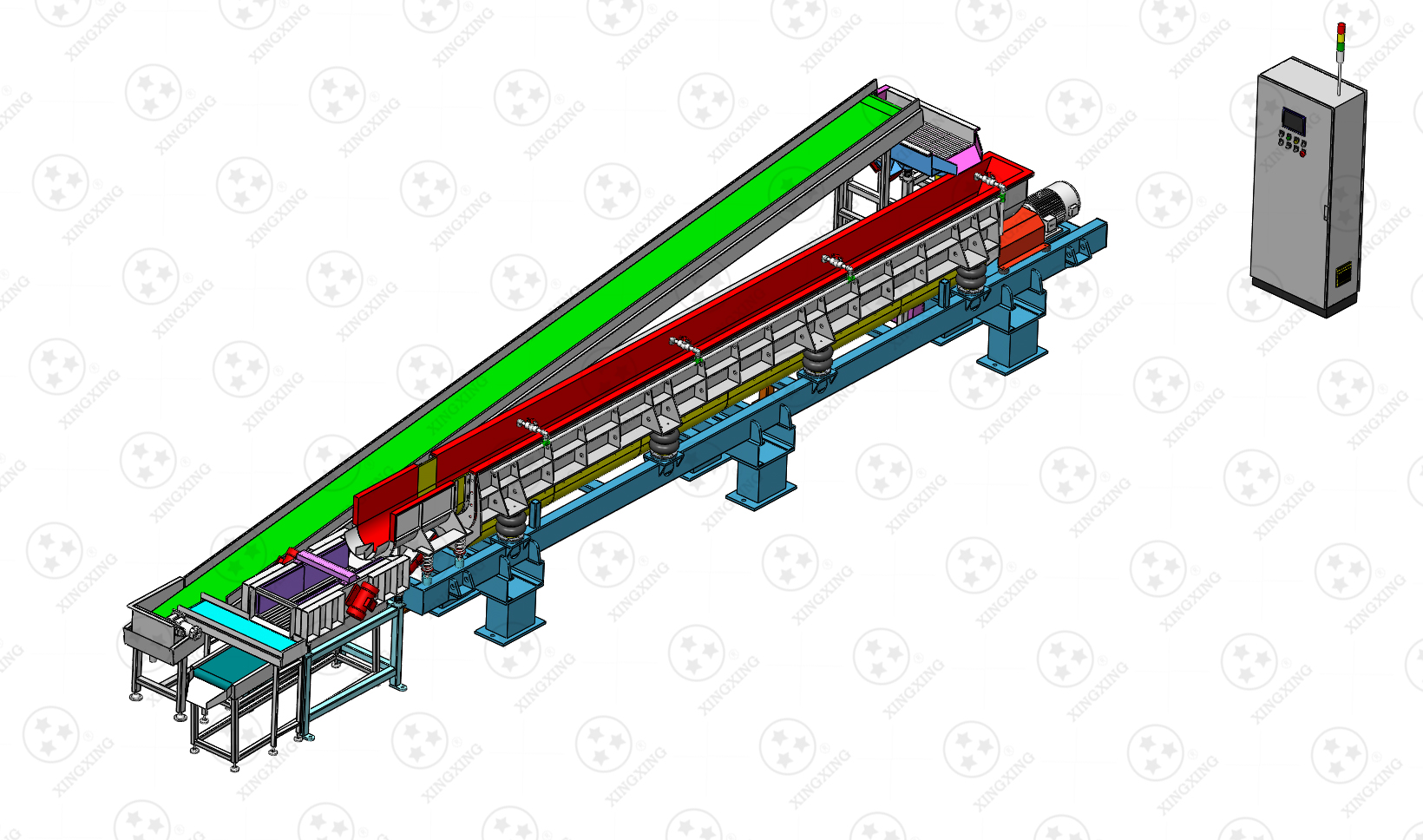

drawing

parameter

Huzhou Xingxing Abrasive Co., Ltd. is a company specializing in surface finishing field. Our company has been engaged in this field since 1 9 9 7. We are a reputable nation-wide supplier of mass finishing media, mass finishing machinery and ceramic grinding balls....Learn More