Focus on Surface Finishing For 30 Years

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

Features

1. This equipment is suitable for deburring, descaling, chamfering and polishing of various workpieces of metal and non-metal products, especially for surface finishing of complex parts with cavities.

2. Without destroying the internal structure of the workpiece, remove the surface oxide layer, improve the surface roughness, remove the stress of the workpiece, and improve the surface strength of the workpiece.

3. Using the principle of planetary rotation and centrifugal motion, the workpiece and polishing abrasive are forced to flow during the revolution and rotation, so that the friction between the abrasive and the workpiece is increased, and the micro-cutting process on the surface of the workpiece is realized, and the surface finishing treatment efficiency is improved. Increased by 10-20 times.

4. This type of equipment is suitable for batch grinding of small and medium-sized workpieces. It can match the appropriate size of the grinding barrel and the corresponding capacity model according to the size of the workpiece.

configuration options

1. It adopts high-strength nylon gear or chain transmission, and the selection varies according to the model.30 liters, 58 liters, 80 liters, and 120 liters can all adopt nylon gear transmission design, and 30 liters can adopt either chain transmission design, nylon gear transmission design, or synchronous belt transmission design.

2. Independent control electric cabinet: it is convenient for the safe operation of the equipment and protects the motor from overloading. An automatic PLC electric control cabinet can also be provided.

3. Frequency converter: the frequency range is adjustable, and the effect of adjusting the speed of the grinding barrel can be achieved by adjusting the running speed of the equipment motor.

4. It adopts arc sliding door design and is equipped with a safety contact switch.

5. The grinding barrel is made of wear-resistant polyurethane, which has the characteristics of acid and alkali resistance, low cost and long service life. The grinding barrel can also be made of natural rubber, which has the characteristics of high temperature resistance.

6. Multiple partitions are poured inside the grinding barrel to isolate large workpieces that are afraid of collisions, so as to avoid mutual damage between workpieces. 58 liters, 80 liters, and 120 liters are suitable for models.

7. Vibration sorting sieve car: realize automatic separation of workpiece and abrasive, applicable to 58 liters, 80 liters, 120 liters and 300 liters models.

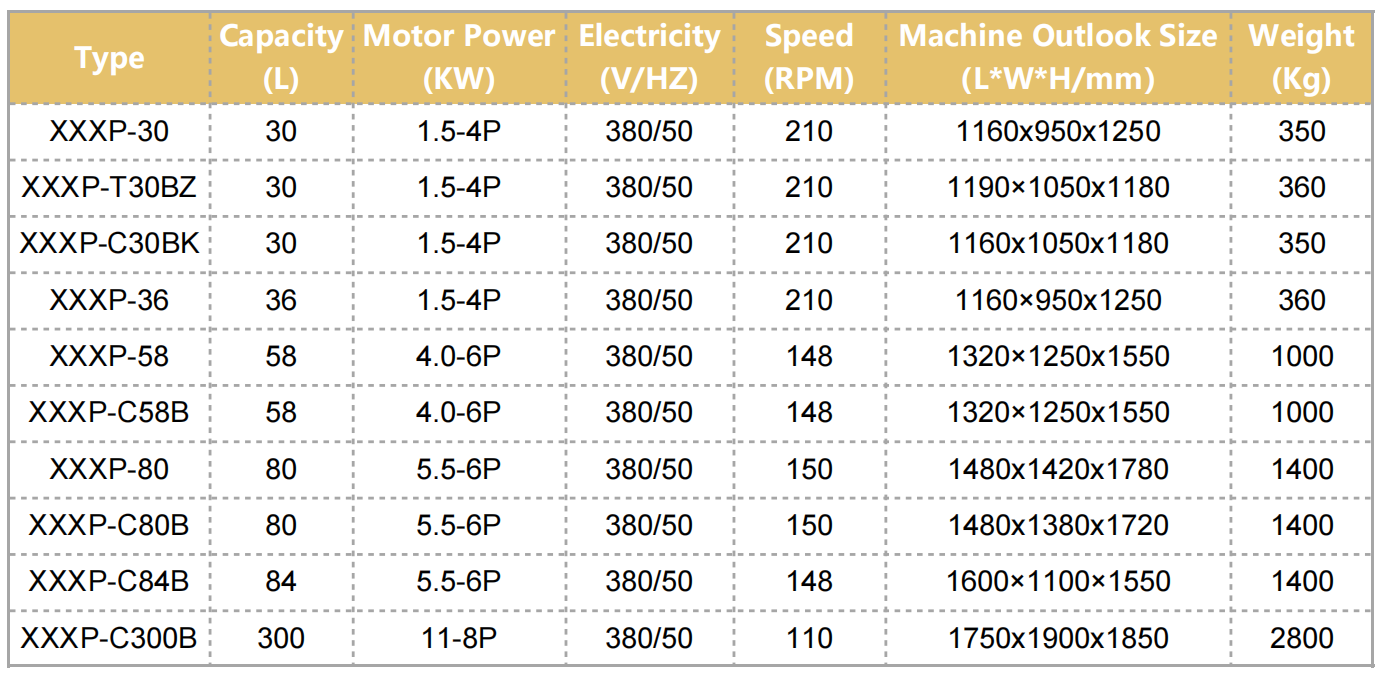

parameter

Huzhou Xingxing Abrasive Co., Ltd. is a company specializing in surface finishing field. Our company has been engaged in this field since 1 9 9 7. We are a reputable nation-wide supplier of mass finishing media, mass finishing machinery and ceramic grinding balls....Learn More